Air Shower

- Air shower works as partial clean equipment installed at the partition between the clean room and non-clean rooms to shower the personnel or matters before entering the clean area. This unit helps to remove dust effectively and maintains the normal working status. All our Air Showers are assembled and tested directly in the factory and supplied after hard quality testing. These units are completely microprocessor controlled self contained unit and equipped with air filtration systems, blowers, motors, controls, inter locking doors, lighting and electrical panel. Although we offer air showers in varies sizes and packages, we also provide customized designs meeting your special needs.

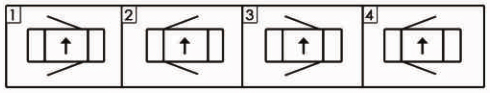

- Straight Entry Straight Exit

- Straight Entry Right Exit

- Straight Entry Left Exit

- Straight Entry Right and Left Exit

Types of Cleanroom

| 1 | Product | Aeromech® Air Shower |

| 2 | Type | Re circulatory type , Standard type |

| 3 | Dimensions | As per drawings enclosed. |

| 4 | MOC | Galvanized Iron with PU coated / Stainless Steel – Satin Finish |

| 5 | Pre Filter | Aeromech Make Pre Filter with Micro Glass Fibre Media of EU - 4 Rating. |

| 6 | Supply HEPA Filter | Imported Minipleat HEPA Filter efficiency 99.97% Down to 0.3µ H-13 Rating. |

| 7 | Floor | 2mm thick GI/ SS Sheet with ESD Mat on Top |

| 8 | Motor Blower Assembly | Air Conditioned air to be Supplied by client with required Airflow Quantity |

| 9 | Nozzle Position | Right/ Left / Top with direction adjustable |

| 10 | Emergency Switch | Panic Switch in side and Out Side |

| 11 | Lights | Fluorescent Tube with Milky White Diffuser. |

| 12 | Other Electricals | 3 Pin Socket, 15 AMP - 1 No. - On / Off Switches with Indicator. |

| 13 | Performance | |

| 14 | Air Cleanliness | First Air From Filter Class ISO - 5 (as per ISO - 14644-1). |

| 15 | Air Flow Rate | 25 ± 2 mps. or 5000 FPM ± 300FPM |

| 16 | Illumination Of Light | Minimum 800 Lux on work table |

| 17 | Noise Level | Less than 75 db on Scale 'A' When Ambient sound Level is not Greater than 57 db on Scale 'A' |

| 18 | Vibration Level | Minimum. |

Door Orientation:

Air shower custom Units with Right Angle Entry/ Exit doors are available onrequest