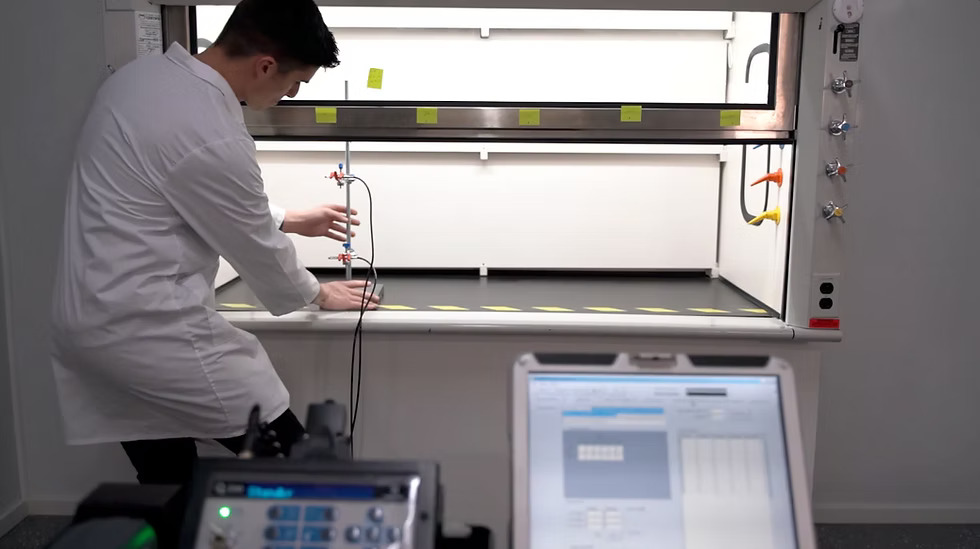

Understanding Fume Hoods and Their Role in Lab Safety

Fume hoods are essential in laboratory environments. They protect workers from hazardous fumes, vapours, and airborne contaminants. Regular testing ensures these systems function effectively, reducing exposure risks.

Key Reasons for Regular Fume Hood Testing

1. Ensuring Proper Containment

Fume hoods work by drawing in harmful substances and venting them safely. Without regular testing, leaks or malfunctions could compromise safety, putting lab personnel at risk.

2. Maintaining Airflow Efficiency

Airflow performance is critical for proper ventilation. Testing verifies that face velocity meets required standards, ensuring hazardous fumes do not escape into the workspace.

3. Compliance with Safety Regulations

Regulatory bodies like OSHA and ANSI mandate periodic fume hood testing. Compliance prevents legal issues, protects workers, and ensures laboratories operate within safety guidelines.

4. Identifying Wear and Tear

Over time, fume hoods experience wear. Filters clog, motors degrade, and ducts accumulate residue. Routine inspections help detect problems early, preventing costly repairs and safety hazards.

5. Protecting Laboratory Personnel

The primary purpose of fume hoods is to safeguard researchers. Malfunctioning equipment increases the risk of chemical exposure, leading to health complications such as respiratory issues or chemical burns.

Types of Fume Hood Testing

Face Velocity Testing

This test measures airflow speed at the hood’s opening. A low velocity may indicate improper ventilation, while excessive airflow can create turbulence, reducing efficiency.

Tracer Gas Testing

This method evaluates containment efficiency using gas detection. It identifies potential leaks and verifies that the hood effectively removes hazardous substances.

Smoke Pattern Testing

This test uses visible smoke to check airflow patterns. It helps pinpoint dead zones or backflow issues that could lead to contamination.

How Often Should Fume Hood Testing Be Done?

Most safety standards recommend testing at least once a year. However, high-use environments may require more frequent evaluations to maintain peak performance.

Best Practices for Maintaining Fume Hood Efficiency

- Keep the sash at the recommended height.

- Avoid storing unnecessary items inside the hood.

- Ensure proper lab ventilation and air supply.

- Schedule routine maintenance and inspections.

Conclusion

Fume hood testing is crucial for lab safety. Regular inspections ensure compliance, protect workers, and maintain optimal performance. By prioritizing testing, laboratories create a safer work environment for all personnel.