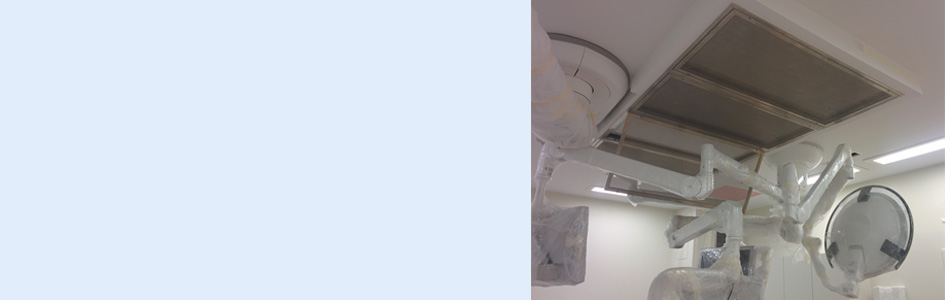

Operation Theatre Laminar Airflow

- The operating theatre ceiling is the most important part of a hospital ventilation system. Also called UCVS (Ultra Clean Ventilation System), these sophisticated systems are actually a combination of a variety of elements, including gas tight welded pressure chambers, air filter housings or filter grids, HEPA filters, priming illumination and air diffusers.

- Laminar Flow Ceiling for Operating Theatres

- to produce a germ- and particle lean area through an unidirectional air flow.

- The system is specially designed and suited for the use in Operating Theatres.

- The requirements according to ISO 14644 Standard and NABH Guidelines

Pressure Chamber

- Air sealed pressure chamber, made out of IS 304 Grade stainless steel 1.2mm thick Sheet

- Smooth inner surfaces, therefore easy to clean and disinfect during filter changes

- Special frame system for the integration of the filter frames, the pressure chamber, all required receptacles of the surrounding air flow stabilizers made out of anodized Aluminium.

- Openings for the supply duct connections

- Air sealed housing for the integration of the stand of the O.T. light and openings for the service of the O.T. light

- Aerosol port

- Port for pressure drop measurement

- Supply air connections as flange made out of IS 304 Grade stainless steel 1.2mm thick sheet

- Lateral attached, air sealed, disinfectant resistant varnished with connection flange for external duct installation.

Diffuser- Frame

- Frame made out of anodized Aluminum profile for the placement of the CG-Diffuser and has rails for the easy and seamless placement of the false sealing or other connecting equipment.

- The Aluminum profile is prepared for the integration of the sterile field and O.T.-illumination, when combined with the optional rail system for the O.T. illumination.

HEPA Filters

- Integrated HEPA Filter-Cells with a frame made out of galvanized sheet steel

- Optimized standard dimensions

- Extremely high filter surface for low initial pressure drops

- EPDM profile gasket

- Change of filters to the clean side

Sterile Air Diffuser CG

- Transparent diffuser with double layer micro mesh, made out of specialized textile

- Assembly and disassembly without screws or tools

- Air-flow optimized frame made out of Aluminum profile

- Pass through of the stand of the O.T. light

- Whole construction to the clean side smooth and without screws

Test port for LAF testing

- Mounted outside of the aluminum frame system with test connection for DEHS testing and pressure drop, varnished RAL 9016.

- Filter surface per m² face area 18,5 m²

- Norms: DIN 1946-4

| Model No | AOT 2408 | AOT 2406 | AOT 1806 |

|---|---|---|---|

| Airflow Volume | 4760 m³/h | 3570 m³/h | 277 m³/h |

| Outer Dimension | W 2400 x D 2400 mm | W 2400 x D 1800 mm | W 1800 x D 1800 mm |

| Height of the Plenum Box | 450 mm | 450 mm | 450 mm |

| HEPA Filter Area | W 2290 x D 2290 mm | W 2290 x D 1710 mm | W 1710 x D 1710 mm |

| Average Velocity | 0.25 m/sec | 0.25 m/sec | 0.25 m/sec |

| No of HEPA Filters | 8 Nos | 6 Nos | 4 Nos |

| HEPA Filter Class as per EN 1822 | H13 | H 13 | H 13 |

| Initial Pressure Drop | 160 Pa | 160 Pa | 160 Pa |

| Final Pressure Drop | 600 Pa | 600 Pa | 600 Pa |

| No for Collar | 6 Nos | 4 No | 4 No |

| Height of Available Ceiling Space (minimum requirement) 550 mm | |||