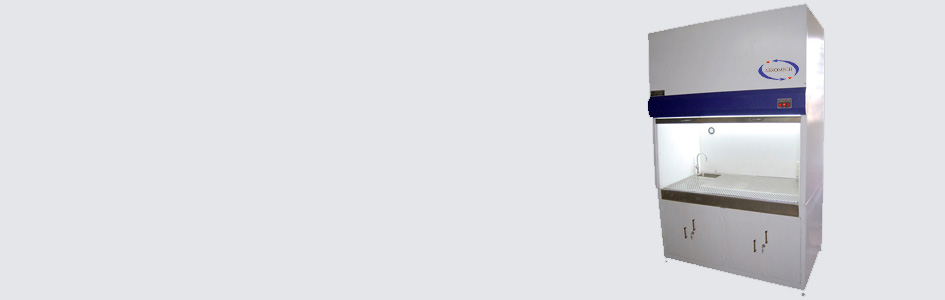

Wet Chemical Bench

Aeromech make Wet Chemical Benches used for wet chemical handling of various applications, electropolishing and/or citric / nitric acid passivation as well as other chemical wet process applications. Typical construction materials include polypropylene, stainless steel, depending on the chemical handling properties required for the application. Our manufactured wet Chemical benches include simple polymer based tanks typically made from polypropylene (PP).

| 1 | Product | Aeromech® Wet Chemical Work Station |

| 2 | Dimensions | As per drawings enclosed. |

| 3 | Protection | Galvanized Iron with PU coated / Stainless Steel – Satin Finish / Wooden laminated |

| 4 | Air Balacing | 0% Recirculation & 100 % Exhaust Air |

| 5 | Exhaust collar | Minimum8” dia PVC pipe |

| 6 | Cleanliness level | ISO Class 5 as per ISO 14644 -1 |

| 7 | Down Flow Velocity | 0.45 ± 0.05mps. or 90 FPM ± 10 FPM |

| 8 | Motor Blower Assembly | Induction Motor with Centrifugal Blower Statically and Dynamically balanced with Suitable Rating and Size. |

| 9 | Mounting | Unique Spring Suspension Systems to take care of Vibration and Noise. |

| 10 | Working Table | Granite Stone/ FRP Moulded Top/ SS 304 Stainless Steel Top. |

| 11 | Front Sash. | Clear Glass Side Panels/ Clear Acrylic panel/ UV Protected Polycarbonate panel |

| 12 | Airflow Monitor | TEK UK make Face Velocity indicator with Alarm. |

| 13 | Lights | Fluorescent Tube with Milky White Diffuser. |

| 14 | Other Electricals | 3 Pin Socket, 15 AMP - 1 No. - On / Off Switches with Indicator. |

| 15 | Performance | |

| 16 | Standard reference | ASHRAE-110 and EN14175-3 |

| 17 | Face Velocity | 0.45 ± 0.05mps. or 90 FPM ± 10 FPM |

| 18 | Illumination Of Light | Minimum 800 Lux on work table |

| 19 | Noise Level | Less than 67 db on Scale 'A' When Ambient sound Level is not Greater than 57 db on Scale 'A' |

| 20 | Vibration Level | Minimum. |

| 21 | Air Cleanliness | Class ISO - 5 (as per ISO - 14644-1). |

| 22 | Air Flow Rate | 0.45 ± 0.05mps. or 90 FPM ± 10 FPM |